Bending is a manufacturing method that uses force to change the form of sheet metal. The sheet metal may be bent at any angle, and a series of bending operations can result in a complicated form or portion. Bending is often defined as distortion along a single axis.

In press brake forming, a work piece is positioned over the die block and a top tool/ punch presses the sheet to form a shape. Usually bending has to overcome both tensile stresses and compressive stresses. When bending is done, the residual stresses cause the material to spring back towards its oriiginal position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. The bend radius refers to the inside radius. The formed bend radius depends on the dies used, the material properties, and the material thickness.

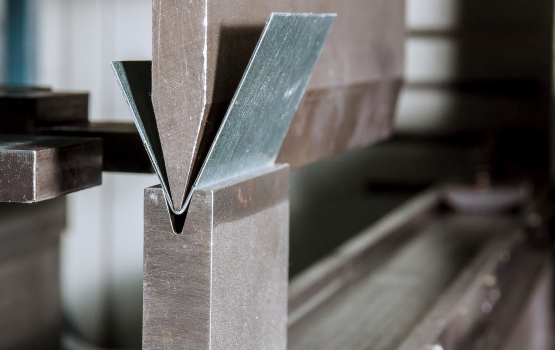

In air bending, the workpiece comes in contact with the outside edges of the bottom die, as well as the punch tip. The punch is then forced past the top of the die into the v-opening without coming into contact with the bottom of the v. The v opening is typically deeper than the angle which is sought in the work piece.

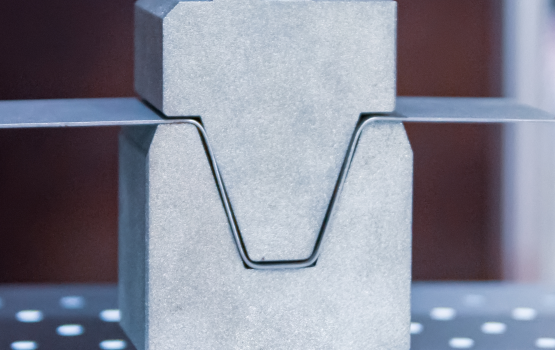

In bottom bending,the punch presses the metal sheet onto the surface of the die, so thr die's angle determines the final angle of the workpiece. With bottoming, the inner radius of the angled sheet depends on the die's radius. The difference between air bending and bottom bending is that the metal sheet takes the exact shape of the botttom die.

Coining is a bending process in which the shape of the punch and bottom die determines the shape of the metal sheet. The punch presses the metal sheet until the top side of the metal sheet takes the shape of the punch and the bottom side takes the shape of the bottom die. There is more tonnage required on this type of bending than in air bending and bottom bending. There is no spring back to worry about in this process.

A roll bender is a mechanical jig having three rollers used to bend a metal bar or sheet into a circular arc. The rollers freely rotate about three parallel axes, which are arranged with uniform horizontal spacing. In roll bending the arrangement of the rolls determines the exact bend of the workpiece. Different curves are obtained by controlling the distance and angle between the rolls. A movable roll provides the ability to control the curve.