Busyload ensures all our manufacturing partners have an efficient Quality Management System (QMS) in place. This enables delivery of every order with expected quality and within the scheduled timeline.

Busyload onboards a manufacturing partner only if they fulfil a set of quality objectives like 100% on-time delivery, compulsory stage-wise documentation of all reports, on-time calibration of inspection devices and so on.

You will receive thorough and timely communication from our team of quality engineers at every stage of the project. We guarantee your custom parts will be built exactly to your specifications.

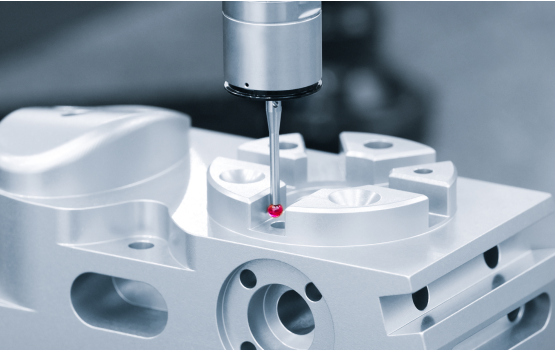

Busyload and the facilities in our Manufacturing Supplier Network have the latest equipment and processes to complete inspections as per customer requirements.

In-line CAD workstations for our engineers

Programs for on-time calibration of all measuring devices.

Coordinate measuring machines (CMM).

Metrology, Shadowgraph devices and mass spectrometer (XRF) to test material compositions.

Optical emission spectroscopy

Positive Metal identification

Ring and thread gauges

Gage blocks and gage pins

A variety of micrometers and calipers

Mechanical, Chemical, metrological, corrosion testing capability