There are a variety of 3D printing materials, including thermoplastics such as

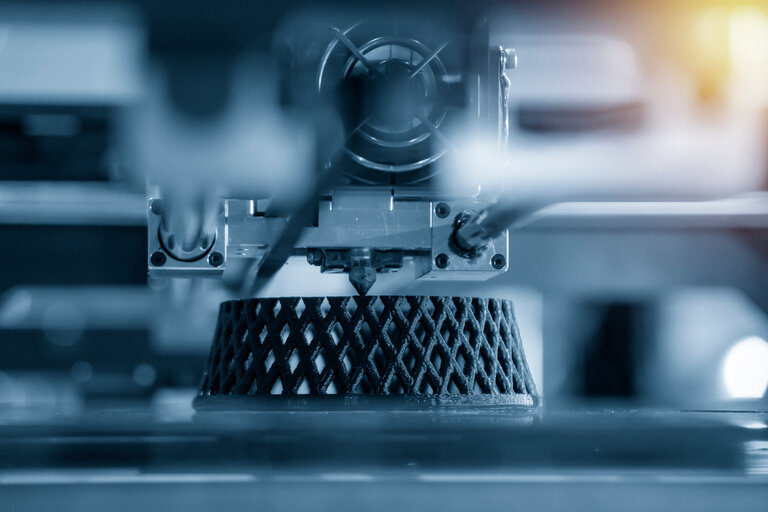

There are three broad types of 3D printing technology - Sintering, Melting, and Stereolithography.

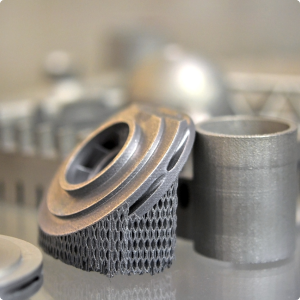

Sintering

It is a technology where the material is heated, but not to the point of melting, to create high resolution items. Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering.

Melting

It is a process in which the machine uses lasers, electric arcs or electron beams to print objects by melting the materials together at high temperatures. This includes powder bed fusion, electron beam melting and direct energy deposition.

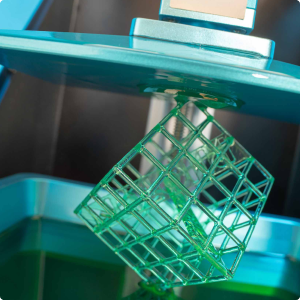

Stereolithography

Stereolithography utilises

photopolymerization to create parts. This technology uses the correct light source to interact with the material in a selective manner to cure and solidify a cross section of the object in thin layers.

This technology allows for the easy creation of bespoke geometric parts where added complexity comes at no extra cost. In some instances, 3D printing is cheaper than subtractive production methods as no extra material is used.

Since no moulds are required, the costs associated with this manufacturing process are relatively low. The cost of a part is directly related to the amount of material used, the time taken to build the part and any post processing that may be required.

Because the process is based upon computer aided designs (CAD), any product alterations are easy to make without impacting the manufacturing cost.

Because the technology allows for small batches and in-house production, this process is ideal for prototyping, which means that products can be created faster than most of the traditional manufacturing techniques, and without the reliance on external supply chains.

Although plastics and metals are the most common materials used in 3D printing, there is also scope for creating parts from specially tailored materials with desired properties. So, for example, parts can be created with high heat resistance, water repellency or higher strengths for specific applications.

While some parts, such as those made from metal, have excellent mechanical properties, many other 3D printed parts are more brittle than those created by traditional manufacturing techniques. This is because the parts are built up layer-by-layer, which reduces the strength.

Estimates suggest that 3D printing is less cost-effective than CNC machining or injection moulding when parts are manufactured in excess of 100 units provided the parts can be manufactured by conventional means.

The accuracy of a printed part depends on the type of machine and/or process used. Some desktop printers have lower tolerances than other printers, meaning that the final parts may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D printed parts may not always be exact.

Most 3D printed parts require some form of post-processing. This may be sanding or smoothing to create the required finish, the removal of support struts which allow the materials to be built up into the designated shape, heat treatment to achieve specific material properties or final machining.

Aerospace

3D printing is used across the aerospace industry due to the ability to create light, yet geometrically complex parts, such as blisks. Rather than building a part from several components, 3D printing allows for an item to be created as one whole component, reducing lead times and material wastage.

Automotive

The automotive industry has embraced 3D printing due to the inherent weight and cost reductions. It also allows for rapid prototyping of a new part for test or small-scale manufacture. So for example, if a particular part is no longer available, it can be produced as part of a small, bespoke run. Alternatively, items or fixtures can be printed overnight and are ready for testing ahead of a larger manufacturing run.

Healthcare

The medical sector has found uses for 3D printing in the creation of made-to-measure implants and devices. For example, hearing aids can be created quickly from a digital file that is matched to a scan of the patient's body. 3D printing can also dramatically reduce costs and production times.

Railways

The rail industry has found a number of applications for 3D printing, including the creation of customized parts, such as arm rests for drivers and housing covers for train couplings.

Robotics

The speed of manufacture, design freedom, and ease of design customization make 3D printing perfectly suited to the robotics industry. This includes work to create bespoke exoskeletons and agile robots with improved agility and efficiency.