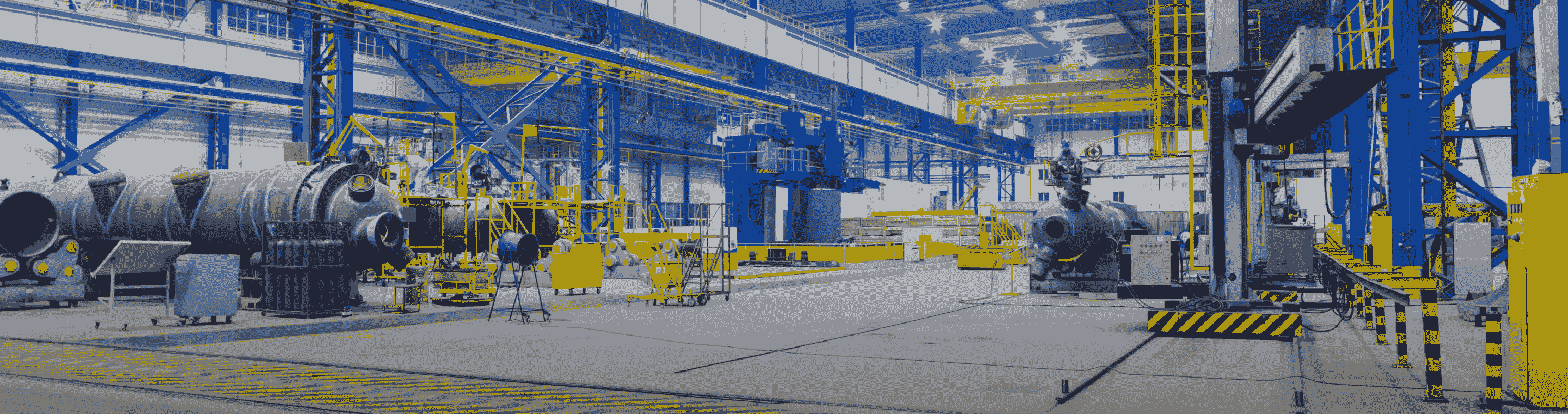

Sheet metal fabrication is defined as the process of turning flat metal sheets into useful products. Various special tools are used in this process to convert sheet metal into useful...

Read more

Laser cutting

Laser cutting is currently the most precise cutting process that is available in the industry and is widely used in sectors like aerospace, automobile...

Read more

Plasma cutting

Plasma cutting service is a high speed on-demand production option for your sheet metal cutting requirements. This cutting process would position itself...

Read more

Bending

Bending is a manufacturing method that uses force to change the form of sheet metal. The sheet metal may be bent at any angle, and a series of...

Read more

Oxy fuel cutting

This is one of the cheapest cutting solutions which is widely used across the industry to cut various materials. Apart from water jet cutting which is...

Read more

Water jet cutting

Water jet cutting process cuts through the material without generating any heat affected zone in the component. Customers looking to cut through...

Read more

Welding

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool...

Read more

Our CNC Machining capabilities include CNC Turning lathes & CNC Milling machines with 3 – axis , 4 – axis & 5 – axis movements to accomplish the given machining task...

Read more

CNC Machining

CNC milling operation is chosen to create precise profiles and details. The speed of the rotating tool and the axis in which it comes in contact with the...

Read more

Conventional Machining

Machining is a method in which a piece of raw material is removed by a managed material removal process into the desired final shape and size..

Read more

Casting is a process in which the liquid molten metal is poured into a cavity whose shape is the same as that of the casting to be produced and allowing it to solidify. After solidification, the...

Read more

Sand casting

In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, where it solidifies to form the cavity shape part...

Read more

Investment casting

Investment casting, also known as precision casting or lost-wax casting, is a process in which a wax pattern is used to shape a disposable ceramic...

Read more

Die casting

Die casting is a method of moulding materials by forcing molten metal under high pressure into a mould cavity. Most die castings are made from non ferro...

Read more

Centrifugal casting

This method is used to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation...

Read more

Forging is the art of heating and shaping the hot metal to a desired form. This involves hammering, rolling, pressing and other ways of obtaining a...

Read more

Drop forging

The process of dropping a hammer onto the heated metal to mould it into the shape of the die is known as drop forging. The die is the part of the tool...

Read more

Roll forging

Roll forging is the process of increasing rods or wires in length. The manufacturer places heated metal bars between two cylindrical rolls with...

Read more

Press forging

In press forging, the main forming factor is compression. The metal sits on a stationary die while a compression die applies continuous pressure,...

Read more

Upsetting

It's the production process under which high pressure deforms metal into high-strength components. It is also called the "hot heading process." Us...

Read more

Start printing your fully functional high quality rapid prototypes just by the click of a button and get them delivered in as fast as 3 days . We have a wide network of manufacturing partn...

Read more

Sintering

Sintering is a technology where the material is heated, but not to the point of melting, to create high resolution items. Metal powder is used for direct...

Read more

Stereolithography

Stereolithography utilises photopolymerization to create parts. This technology uses the correct light source to interact with the material...

Read more

Melting

Melting is a process in which the machine uses lasers, electric arcs or electron beams to print objects by melting the materials together...

Read more

Most of the manufactured components will need to be post processed to either enhance its properties or protect its current form . We offer various types of heat treatment processes...

Read more

Surface treatment

Surface treatment refers to the various methods to treat the surface of a part to protect it from corrosion, improve wear resistance...

Read more

Heat treatment

Heat treatment is an operation involving the heating and cooling of a metal or an alloy in the solid state to obtain certain desirable properties without chan...

Read more

Get your injection moulded parts for your prototypes or productions parts from a wide range of material options and moulding methods. Our team of manufacturing partners have...

Read more

We offer turnkey solutions for a number of industries that include the following . Our team of industry experts will steer the project right from the concept...

Read more