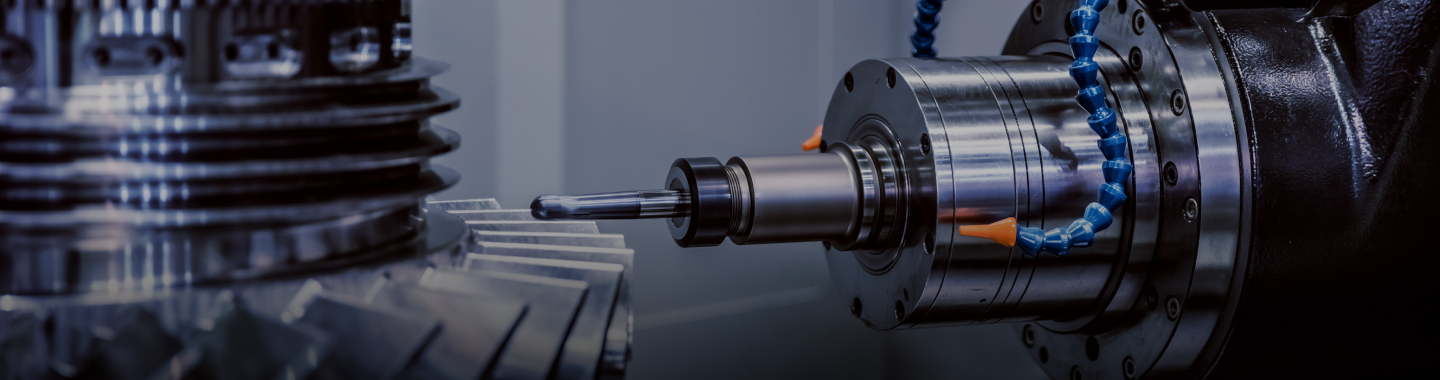

CNC milling is a process of selectively removing material from a work piece using a cutting tool placed on a spinning spindle. The raw material is fastened to a table, which moves or rotates on multiple planes, allowing the tool to operate from a variety of angles.

CNC milling operation is chosen to create precise profiles and details . The speed of the rotating tool and the axis in which it comes in contact with the work piece depends on the G – code fed into the machine and the number of axes in which the tool and work piece is capable of moving.

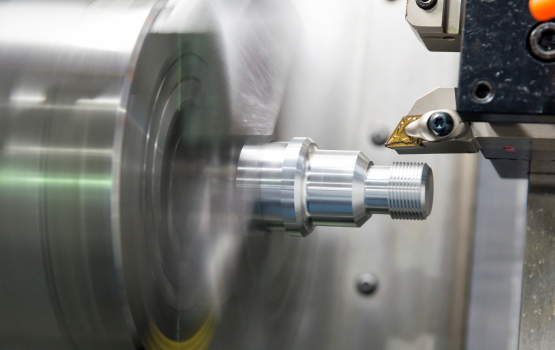

Turning is a machining process that employs single-point cutting tools to remove material from a rotating work piece. Operational capabilities of the turning process include boring, facing, grooving, and thread cutting. CNC turning can produce cylindrical parts with external and internal features such as slots, tapers, and threads.

CNC turning also addresses some of the manufacturing issues connected with CNC milling . For example, it makes it simple to manufacture undercuts and relief grooves, whereas CNC milling machines require specialized cutting tools to perform the same.