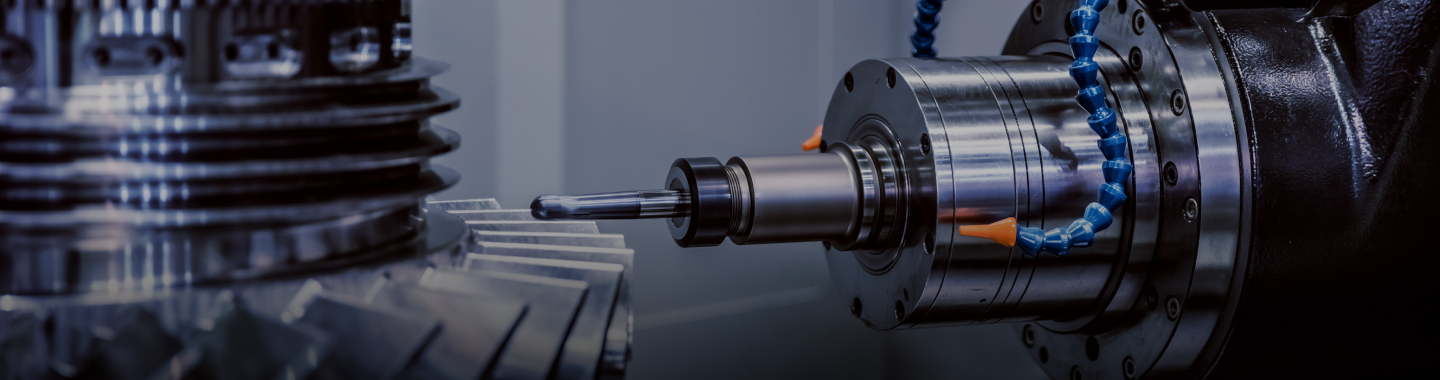

CNC machining is a subtractive manufacturing process that typically employes computerized controls and machine tools to remove layers of material from a stock piece-known as the blank or work piece-and produces a custom-designed part.

Our CNC Machining capabilities includes CNC Turning lathes & CNC Milling machines with 3-axis, 4 axis & 5-axis movements to accomplish the given machining tash impeccably. We have partnered with more than 400+ machine shops who have been manufacturing high precision parts for aerospace, automobile and other sectors where accuracy and tolerance is of vital importance.

Due to the high precision that CNC technology offers , they are used in a wide variety of industries, including the aerospace, medical, and electronics .

In the aerospace industry, they are used to fabricate manifolds, bushings, landing gear parts and a number of other precision components .

The medical industry heavily relies on CNC machinery to create prostheses, medical instruments, and other FDA-approved medical devices.

CNC milling machines play a crucial role in the operation of other modern-day manufacturing technologies. For example, the high-precision copper mold patterns and cavities used in the injection molding process are usually created using CNC mills.

CNC turning machines are excellent for producing cylindrical forms or pieces that are symmetrical near their axis, such as a chess pawn, bolts, rivets, ball bearings, washers and finds its application in a number of industries .

Additionally, CNC machines are used to create heat sinks, amplifier housings, and other electronic parts used in the electronics industry.

Machining is a method in which a piece of raw material is removed by a managed material removal process into the desired final shape and size.. As it removes material & decreases the material mass this is a subtractive process. The conventional machining process is also known as traditional machining process. Because of the abrasive reinforcement and inhomogeneous structure, traditional machining procedures are known to produce less precise products compared to CNC Machined components.

In addition to the regular conventional machines our manufacturing partners possess a number of rare machines with various capabilities to make every machining task possible with given tolerance. These includes lathe machines, Milling machines, Drilling machines, Grinding machines, Vertical turret lathes, Horizontal Boring machines, Gear machines, Gear Hobbing machines etc.